Waterjet cutting provides tremendous flexibility in plate processing and manufacturing. This cutting method is not only climate-friendly but the results are always smooth, uniform and burr free.

It is recognized as one of the fastest growing processes to cut material. It provides many advantages that can reduce costs and increase efficiency.

The Machines

(1) CNC Flow Mach 4 Waterjet

- 157″ x 235″ cutting area

- 100 hp [90,000 psi] intensified pump

- 2 dynamic waterjet cutting heads

- tolerance +/- .001 to +/- .005

(1) CNC Waterjet Cutting System

- 96″ x 144″ cutting area

- 50 hp blast pump

- CNC Windows based controller

The Capabilities

- Cuts a wide range of materials from 20 gauge to 4 inch thick

- Cuts metals like carbon, alloy, stainless steel, aluminum, bronze, brass, and copper

- Suitable for cutting heat sensitive types of material including rubber, plastics, glass, composites

- Waterjet system capable of piercing most materials without starting holes

- Standard cutting tolerance +.005 to +.010

- Capable of cutting parts u-p to 157” x 235”

The Process

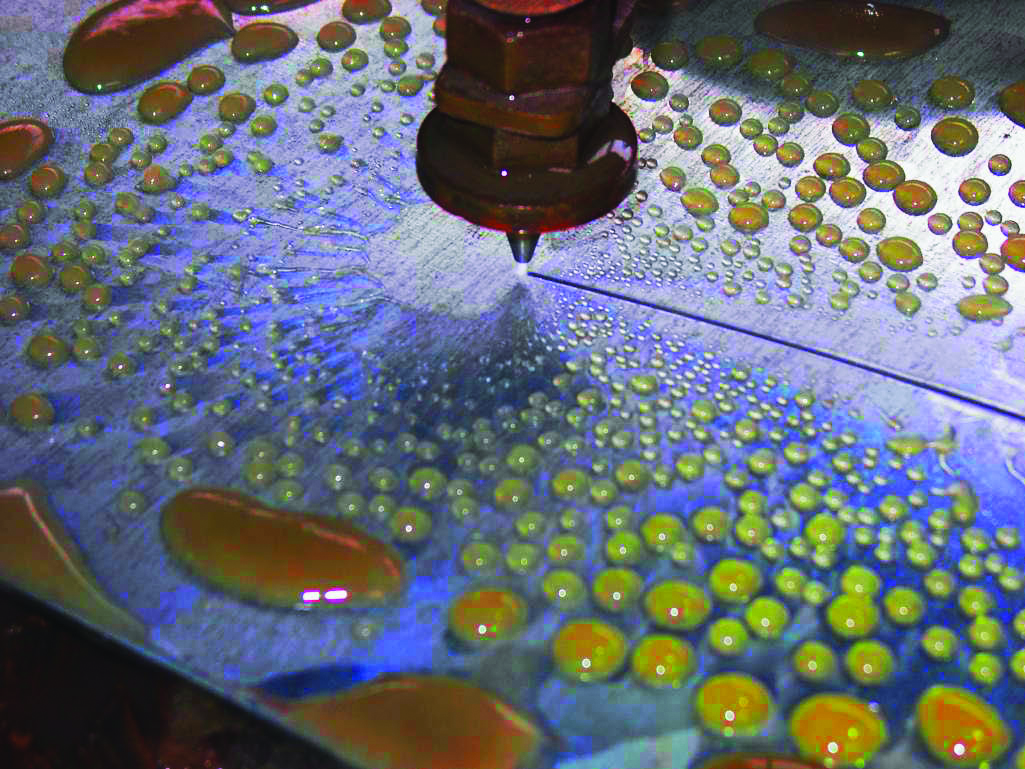

The process begins with pressurizing water exceeding 90,000 psi to produce the required energy for cutting. At this pressure, the water stream is traveling close to 2,500 miles per hour which is more than three times the speed of sound.

The pressurized pump forces water through an opening in the cutter head to form an ultra high pressure stream. This stream is capable of cutting materials. This high pressure water stream can cut any shape with edge quality that requires no secondary finishing.

Waterjets do not cut with the pressure but instead with velocity. The water pressure is exchanged for velocity when the water passes out of the cutter head. The higher the water pressure, the higher the stream velocity.

Waterjet cutting is considered a cold cutting technique. The cold cutting process is the ability to cut with little to no heat generated. The little heat that is created is not enough to change the properties of the material.

Source Metals uses an abrasive waterjet to cut metal.

Abrasive waterjet adds an abrasive blasting material into the cutting head that is mixed with a pure waterjet stream. Adding in an abrasive substance to the waterjet stream increases the cutting strength by a thousand times.

The Benefits

- There are no heat affected zones (HAZ) due to the cold cutting process. The cut edge left behind retains its original properties.

- Exceptional edge quality requiring little to no secondary finishing. (Meaning Source Metals is able to start the next cut right away instead of using other resources to refine the edges after a cut.)

- Raw materials maintain their structural integrity

- Eco-friendly; no hazardous gasses or vapors are used

- CNC- Controlled robotic motion eliminates costly, time consuming tool changes to accommodate a variety of shape cutting

- Material thickness does not matter when using the water cutting method.

- No tool changes needed to cut

The Results

What are your waterjet cutting needs?

Call us at 713-466-7310 or fill out the form below.